Examples: hybrid control and impedance control

Hybrid position-force control

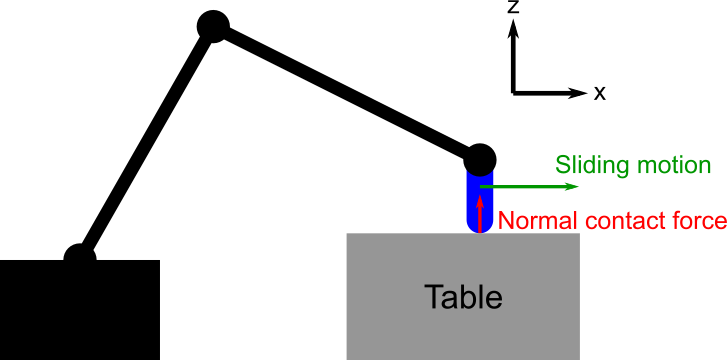

In Section Principles of force control, we have studied force control in a 1-DOF robot. In multi-DOF systems, one usually needs to simultaneously control the force in some task directions and the position in others, a scheme known as hybrid position-force control. Consider for instance the task of sliding the robot end-effector on a tabletop, which can be found in assembly or grinding.

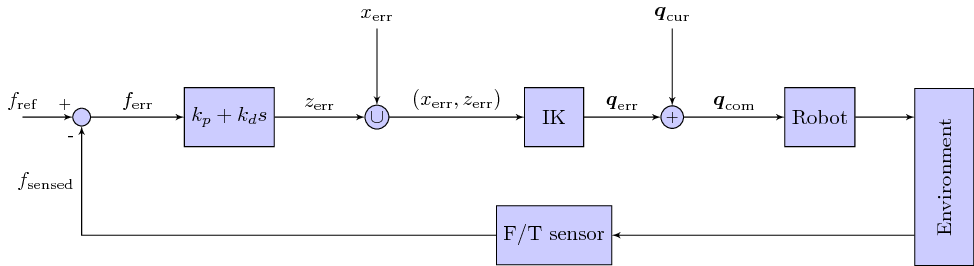

To achieve this task, one needs to control the normal contact force (along the z-axis) to be at some positive values (for example ), while controlling the position along the x-axis (sliding motion). This can be achieved by the following hybrid position-force controller.

The leftmost part of the hybrid scheme is similar to a PD force controller (see Section Principles of force control, which transforms the force tracking error in the z-axis into a position tracking error in the z-axis. Next, is combined with the position tracking error in the x-axis to obtain a task-space position tracking error .

Note that can be easily derived from the desired motion in the x-axis . For instance, if the desired motion is to slide towards the right with a velocity , then , where is the controller time step (assuming a digital implementation).

Next, the task-space position tracking error is translated into a configuration-space error by differential Inverse Kinematics, which can be finally fed into the robot internal position controller.

Example: Hybrid control in Gazebo

We go through the same example as in Robot simulation in ROS/Gazebo in order to pick up the box and retreat from the table surface. Note however the following differences

- We use another ROS launch file, which in particular loads different controllers, see below;

- We use instead of so as to have real-time access to the joint position;

- We use to access force/torque measurements.

First, we start the Gazebo environment in Terminal 1 and run robot controllers launch file in Terminal 2

# Terminal 1

roslaunch osr_gazebo cubes_task.launch

# Terminal 2

roslaunch osr_control controllers_force_control_demo.launch

Next, run a similar code as in Robot simulation in ROS/Gazebo up to the retreating move

python

import rospy

import criros

import collections

import copy

import time

import numpy as np

import openravepy as orpy

import tf.transformations as tr

from osr_openrave import kinematics, planning

from geometry_msgs.msg import WrenchStamped

from osr_control.controllers import GripperController, JointPositionController, FTsensor

rospy.init_node('setting')

env = orpy.Environment()

if not env.Load('worlds/cubes_task.env.xml'):

rospy.logerr('Failed to load the world. Did you run: catkin_make install?')

exit(1)

env.SetDefaultViewer()

Tcamera = tr.euler_matrix(*np.deg2rad([-120, 13, 135]))

Tcamera[:3,3] = [1, 1, 2]

env.GetViewer().SetCamera(Tcamera)

robot = env.GetRobot('robot')

manipulator = robot.SetActiveManipulator('gripper')

robot.SetActiveDOFs(manipulator.GetArmIndices())

taskmanip = orpy.interfaces.TaskManipulation(robot)

js_rate = criros.utils.read_parameter('/joint_state_controller/publish_rate', 250.0) #read publish rate if it does exist, otherwise set publish rate

T = 1. / js_rate

rate = rospy.Rate(js_rate)

# Scale down the velocity and acceleration limits

robot.SetDOFVelocityLimits(robot.GetDOFVelocityLimits()*0.4)

robot.SetDOFAccelerationLimits(robot.GetDOFAccelerationLimits()*0.2)

iktype = orpy.IkParameterization.Type.Transform6D

success = kinematics.load_ikfast(robot, iktype)

if not success:

rospy.logerr('Failed to load IKFast for {0}, manipulator: {1}'.format(robot.GetName(), manipulator.GetName()))

IPython.embed()

exit(1)

# Load links stats for finding closest IK solutions

statsmodel = orpy.databases.linkstatistics.LinkStatisticsModel(robot)

if not statsmodel.load():

rospy.loginfo('Generating LinkStatistics database. It will take around 1 minute...')

statsmodel.autogenerate()

statsmodel.setRobotWeights()

statsmodel.setRobotResolutions(xyzdelta=0.01)

joint_controller = JointPositionController()

gripper_controller = GripperController()

ft_sensor = FTsensor()

cube = env.GetKinBody('cube02')

cube_centroid = cube.ComputeAABB().pos()

Tgrasp = tr.euler_matrix(0, np.pi, 0)

Tgrasp[:3,3] = cube_centroid

qgrasp = kinematics.find_closest_iksolution(robot, Tgrasp, iktype)

axes = []

axes.append( orpy.misc.DrawAxes(env, Tgrasp, dist=0.05) )

traj = planning.plan_to_joint_configuration(robot, qgrasp)

robot.WaitForController(0)

traj_spec = traj.GetConfigurationSpecification()

traj_duration = traj.GetDuration()

step_num = traj_duration // T

#Here we do not use trajectory controller instead we use joint position controller

#It means that we sample many points on the trajectory, which is given by IK fast solver

#Robot will be moving point by point and follow the specified trajectory

for t in np.append(np.arange(0,traj_duration, T),traj_duration):

joint_controller.set_joint_positions(list(traj_spec.ExtractJointValues(traj.Sample(t),robot, manipulator.GetArmIndices())))

robot.SetDOFValues(list(joint_controller.get_joint_positions()), manipulator.GetArmIndices())

rate.sleep()

gripper_controller.command(0.05)

taskmanip.CloseFingers()

gripper_controller.wait()

robot.WaitForController(0)

robot.Grab(cube)

gripper_controller.grab('{0}::link'.format(cube.GetName()))

Tretreat = np.array(Tgrasp)

Tretreat[2,3] += 0.05

Tretreat[0,3] -= 0.1

axes.append( orpy.misc.DrawAxes(env, Tretreat, dist=0.05) )

qretreat = kinematics.find_closest_iksolution(robot, Tretreat, iktype)

traj = planning.plan_to_joint_configuration(robot, qretreat)

robot.WaitForController(0)

traj_spec = traj.GetConfigurationSpecification()

traj_duration = traj.GetDuration()

step_num = traj_duration // T

for t in np.append(np.arange(0,traj_duration,T),traj_duration):

joint_controller.set_joint_positions(list(traj_spec.ExtractJointValues(traj.Sample(t), robot, manipulator.GetArmIndices())))

robot.SetDOFValues(list(joint_controller.get_joint_positions()),manipulator.GetArmIndices())

rate.sleep()

time.sleep(2)

Now, move the box down to the table surface until contact

python

dt = 1. / js_rate

Kf = 5000.

Kp = np.array([1., 1., 1.]) * 1.

Kv = np.array([1., 1., 1.]) * 40

Fr = np.array([0., 0., -15])

qc = joint_controller.get_joint_positions()

Fe_prev = np.zeros(3)

xf = np.zeros(3)

dxf = np.zeros(3)

rospy.loginfo('Going down')

wrench_offset = ft_sensor.get_filtered_wrench()

link_idx = [l.GetName() for l in robot.GetLinks()].index('robotiq_85_base_link')

link_origin = robot.GetLink('robotiq_85_base_link').GetTransform()[:3,3]

J = np.zeros((6,6))

twist = np.zeros(6)

while not rospy.is_shutdown():

q_actual = joint_controller.get_joint_positions()

robot.SetDOFValues(q_actual, manipulator.GetArmIndices())

We = ft_sensor.get_filtered_wrench() - wrench_offset

bTe = manipulator.GetEndEffectorTransform()

bXeF = criros.spalg.force_frame_transform(bTe)

Wb = np.dot(bXeF, We)

Fb = -Wb[:3]

Fr[0:2] = Fb[0:2]

if np.linalg.norm(Fb) >= np.linalg.norm(Fr):

rospy.loginfo('Surface contacted, preparing for sliding')

break

# Force PD compensator

Fe = (Fr - Fb) / Kf

dFe = (Fe - Fe_prev)

Fe_prev = Fe

dxf = (Kp*Fe + Kv*dFe) * dt

xf += dxf

twist[:3] = dxf

# Velocity-based operational space controller

J[:3,:] = robot.ComputeJacobianTranslation(link_idx, link_origin)[:,:6]

J[3:,:] = robot.ComputeJacobianAxisAngle(link_idx)[:,:6]

dqc = np.linalg.solve(J, twist)

qc += dqc

joint_controller.set_joint_positions(qc)

rate.sleep()

# Safety limits: displacement and max force

if np.linalg.norm(Fb) >= 40.:

rospy.loginfo('Maximum force exceeded')

break

time.sleep(2)

Slide on the surface using hybrid control

python

vlin = 0.006 #linear velocity

dr_slide = [1.,0.] # sliding direction on x-y plane

dt = 1./ js_rate # time step

x0,y0,z0 = manipulator.GetEndEffectorTransform()[:3,3] #position of gripper at the starting point

xr = [x0,y0,z0]

timeout = 20

Kp_pos = np.array([1, 1, 0]) #proportional gain of position controller

Kv_pos = np.array([0.05, 0.05, 0]) #derivative gain of position controller

Kp_force = np.array([0, 0, 3.4e-5]) #proportional gain of force controller

Kv_force = np.array([0, 0, 5e-6]) #derivative gain of force controller

bTe = manipulator.GetEndEffectorTransform()

bXeF = criros.spalg.force_frame_transform(bTe) # transformation matrix that convert wrench wrt body frame to wrench in space frame

wrench_offset = ft_sensor.get_filtered_wrench()

We = ft_sensor.get_filtered_wrench() - wrench_offset

Wb = np.dot(bXeF, We) #wrench (the environment inserts on the end effector) is represented in space frame

Fe_prev = -Wb[:3] #extract force vector only, negative sign indicates this is the force inserted on the environment by the robot

xe_prev = [x0, y0, z0]

qc = joint_controller.get_joint_positions()

force_data = list() #data for graph

time_data = list()

initime = rospy.get_time()

link_idx = [l.GetName() for l in robot.GetLinks()].index('robotiq_85_base_link')

link_origin = robot.GetLink('robotiq_85_base_link').GetTransform()[:3,3]

J = np.zeros((6,6))

twist = np.zeros(6)

rospy.loginfo('Sliding')

while not rospy.is_shutdown() and (rospy.get_time() - initime) < timeout:

xr[0] += dr_slide[0] * vlin * dt

xr[1] += dr_slide[1] * vlin * dt

q_actual = joint_controller.get_joint_positions()

robot.SetDOFValues(q_actual, manipulator.GetArmIndices())

# Transform wrench to the base_link frame

We = ft_sensor.get_filtered_wrench() - wrench_offset

bTe = manipulator.GetEndEffectorTransform()

bXeF = criros.spalg.force_frame_transform(bTe)

Wb = np.dot(bXeF, We)

Fb = -Wb[:3]

Fr = np.array([0., 0., -15])

Fr[:2] = Fb[:2]

Fe = Fr - Fb

dFe = (Fe - Fe_prev) / dt

Fe_prev = Fe

dxf_force = (Kp_force*Fe + Kv_force*dFe) * dt

xb = manipulator.GetEndEffectorTransform()[:3, 3]

xe = xr - xb

dxe = (xe - xe_prev)

xe_prev = xe

dxf_pos = (Kp_pos*xe + Kv_pos*dxe) * dt

dxf = dxf_force + dxf_pos

twist[:3] = dxf

# velocity-space IK

J[:3,:] = robot.ComputeJacobianTranslation(link_idx, link_origin)[:,:6]

J[3:,:] = robot.ComputeJacobianAxisAngle(link_idx)[:,:6]

dqc = np.linalg.solve(J, twist)

qc += dqc

force_data.append(Fb[2])

time_data.append(rospy.get_time() - initime)

joint_controller.set_joint_positions(qc)

rate.sleep()

rospy.loginfo("Complete hybrid control demo")

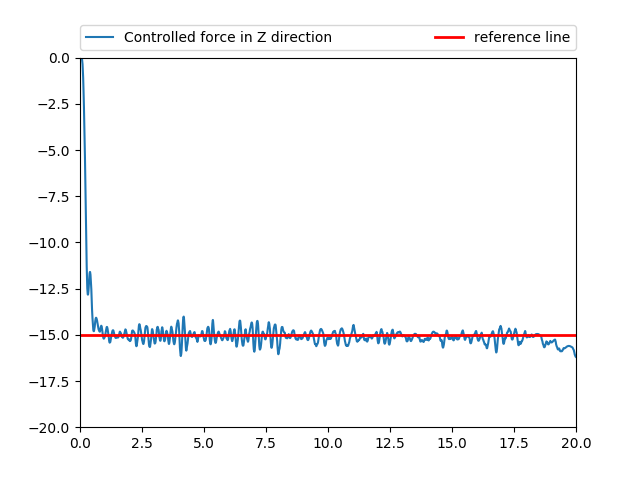

Plot the force data

python

import matplotlib.pyplot as plt

plt.ion()

plt.plot(time_data,force_data, label = "Force measured in the Z direction")

plt.axhline(y=-15.0, xmin=0, xmax=15., linewidth=2, color = 'r',label = "Reference")

plt.axis([0,20,-20,0])

plt.legend(bbox_to_anchor=(0., 1.02, 1., .102), loc=3,

ncol=2, mode="expand", borderaxespad=0.)

plt.show()